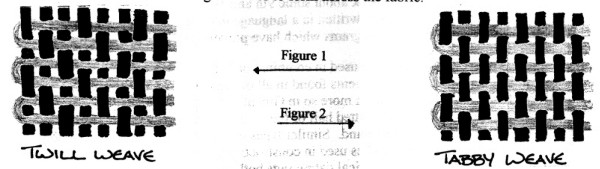

Materials - WoolT+C gives considerable detail about the types of fabrics found, more than the very general discussion of wool textiles and terms given here. 'Worsted wool' is made from long haired sheep. Its wool is washed, then carefully combed, usually using only one brush, to keep all the fibers parallel to one another. When the fiber is removed from the comb it is spun continuing to keep all the fibers parallel to one another. This creates a very strong, smooth yarn. Fabrics made from these yarns are very fine and smooth. Their most common modern use is in men's and women's suits. In the fourteenth century they were used for both the outside and the lining of garments. They were usually woven into twills, but can also be found as tabbies. They would have been fulled only, and prized for their smooth finish. 'Woolens' are generally made from short haired sheep. After washing, the wool is carded with two carders (brushes), to remove imperfections and align the fibers. When the fiber is removed from the combs it is rolled up and spun by pulling the fibers out perpendicular to the roll. This yarn is fuzzy from all the ends of the hairs sticking out perpendicular to the twist. Cloth made from such a yarn is also fairly fuzzy, making it quite warm. Modern uses of this fabric include blankets and men's sports (tweed) jackets. In period, this type of cloth would often be fulled, teased, and then shorn so that the hairs would all be of the same height, giving a smooth, but nappy appearance, where the individual yarns that make the weave would not be discernible. When fabric is woven, the vertical threads, or warp yarns, which run the length of the finished fabric, are held on the loom; and the horizontal, or weft, yarns are inserted through them. The warp yarns are sometimes known as selvedge threads because they run parallel with the strengthened edge, or selvedge of the fabric. The most common pattern of weaving the weft through the warp is alternately over and under the warp threads. This produces a plain weave fabric, frequently called "tabby weave". The next most common is called "Twill weave". It is made by passing the weft threads over two warps, then under either one ('three shaft twill') or two warps ('four shaft twill'). This pattern is continued down the fabric, each time shifting the starting point over one warp thread. This causes what look like diagonal lines to form across the fabric.

Tabby weave (figure 1), which has always been used for linen, became popular for woolens in this time because it was a simple and quick weave to set up on the loom and it provided an even surface for the finishing process of fulling. Tabby is commonly used today for sheets, and fine tea towels. For many years people weaving their own cloth used twill weaves to achieve a cloth that was fairly thick and durable, with an interesting surface texture. Twill weaves (figure 2) give the appearance of diagonal lines, which can be organized to make lozenge or herringbone shapes. Twills were mainly woven from worsted wool in this time and not felted since the felting process which became so popular obscured the subtle patterning. Twills are commonly found today in both jeans and fine suitings. After weaving a fabric would be fulled. Fulling was a process of washing the woven cloth where by it was cleaned of the sheeps natural oils and thickened and shrunk through agitation (in period it was done by hand or foot). Napping or teaseling was a process where a pile was raised on the surface of the textile (using a teasel: a metal comb or brush like implement), making it soft and almost shaggy. Shearing gives the surface of the cloth a haircut, and makes the nap one uniform length. Many fine fabrics in this time were subjected to this process repeatedly being given one, two or three shearings each, with four to seven trecken or nappings per shearing (Munro, in Cloth and Clothing, p. 33). Dying would take place after weaving and fulling (since lanolin, an oil from the sheep, can resist many dyes) and before napping and shearing. The type of loom available to the weaver profoundly affected the type of fabrics a weaver could create. Though out the 13th and 14th century loom technology was changing in Europe. The traditional warp weighted loom was falling into disuse and the horizontal loom was becoming popular. In the far north of Europe (Greenland and Scandinavia), and perhaps in more isolated communities where the warp weighted loom was still in use into the 1400's, fabric for clothing was likely to be fairly narrow, perhaps only 18-27 inches across depending on the weaver. These looms can be used to create a much wider yardage, but the fineness of the resulting fabric is reduced, making it less suitable for garments. Twill patterns (two over, one under) were the common weave with this type of loom, and they were not usually subjected to the same sort of finishing processes as the tabby woven cloth, since the napping would obscure the attractive weave. This type of loom was certainly still in use in Greenland during the 14th century. Excavations have revealed looms that were still strung with weaving in houses dated to this time. (Brown, p 1). The Herjolfesnes garments are made from a woolen four shaft twill (mainly "coarse, twilled frieze"), and none of the pieces found within the garments were wider than 22 inches. Different qualities, from fine to coarse, are mentioned, both in separate garments, and within the same garment at Herjolfesnes On the continent of Europe, however, there is no doubt that the horizontal loom dominated the commercial weaving trade. Guild records from across the major weaving regions in Flanders, England and France remark on the type of textiles that were in production at the time (See Cloth and Clothing in Medieval Europe- C+C) . Horizontal looms are able to produce cloth in very wide widths without sacrificing quality. Table 3.2 in the essay "The Medieval Scarlet" by John Munro (C+C chapter 3) gives the raw measurement as well as the fulled measurement for the length and widths of 'scarlet' and other woolens woven in England and the Low countries between 1282-1554. This table reveals that fabric was fairly routinely woven in widths between 3 and 4 ells wide (one ell = about 27); therefore fabrics were woven between 81 and 108 inches wide. After fulling the width became 54" to 68" wide. Horizontal looms can be set up to weave any sort of cloth, but the easiest type is a tabby weave. Woolen tabby weaves are the most common type of cloth found at the excavations in London (T+C) , though there are quite a number of twills too. |